How Precast Technology Enhances Quality and Durability in Construction

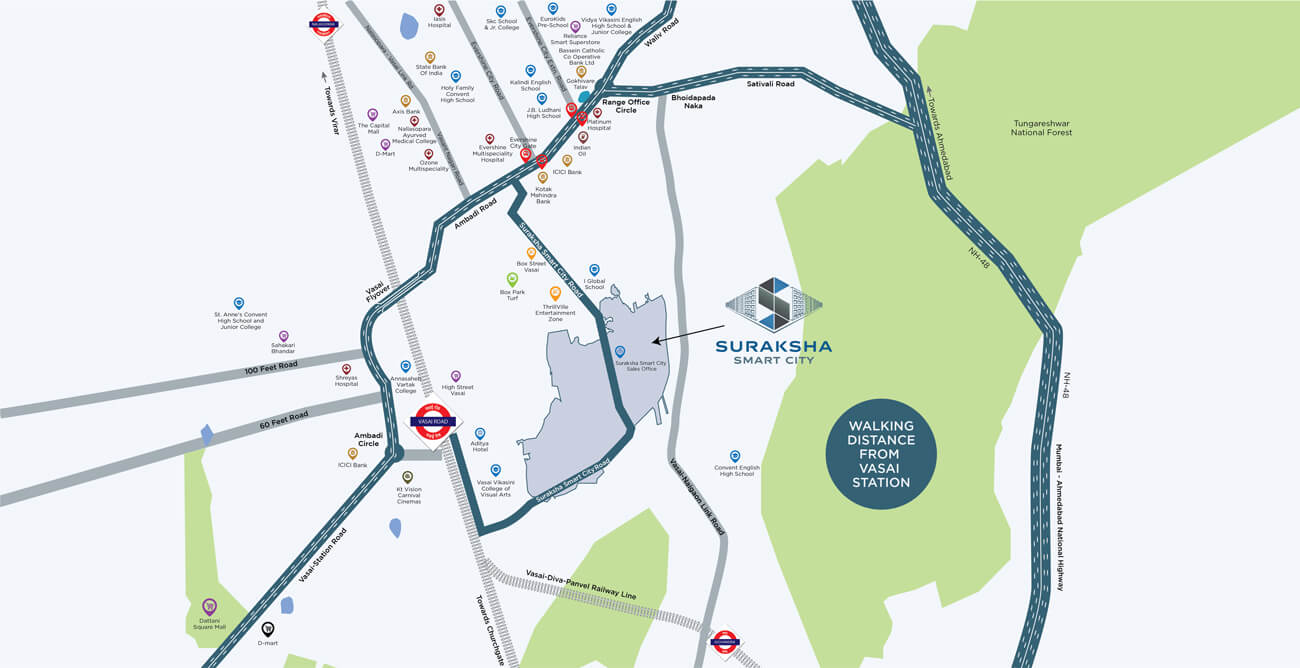

In the rapidly evolving construction industry, the quest for methods that enhance quality, durability, and efficiency is paramount. Precast technology has emerged as a transformative approach, offering significant advantages over traditional construction methods. Suraksha Smart City, a pioneering township in Vasai, exemplifies the successful integration of precast technology, setting new benchmarks in modern construction.

Understanding Precast Technology

Precast technology involves casting concrete elements in reusable molds within a controlled factory environment. These precast components are then transported to the construction site for assembly. This method ensures precision, consistency, and superior quality control compared to on-site casting.

Advantages of Precast Technology

1. Enhanced Quality Control

Manufacturing precast elements in a controlled environment allows for stringent quality checks at every production stage. This meticulous oversight minimizes material variability and ensures each component meets exact specifications, resulting in a uniformly high-quality structure.

2. Increased Durability

Precast concrete is renowned for its robustness and longevity. The controlled curing process enhances the material's strength, making it resistant to adverse weather conditions, corrosion, and wear over time. This durability translates to reduced maintenance costs and extended building lifespans.

3. Accelerated Construction Timelines

Since precast components are manufactured off-site and prepared for immediate installation upon arrival, construction schedules are significantly shortened. This efficiency reduces labor costs and expedites project completion, benefiting both developers and occupants.

4. Environmental Sustainability

Precast technology promotes sustainability by optimizing material usage and minimizing waste. The precision of factory production leads to efficient resource utilization, and the durability of precast structures reduces the need for frequent repairs, contributing to environmental conservation.

Suraksha Smart City's Implementation of Precast Technology

Suraksha Smart City has embraced precast technology to revolutionize its construction processes. The township boasts one of Asia's largest captive precast factories, spanning 16 acres. This facility utilizes advanced 3D casting techniques, ensuring that each component aligns with the project's high-quality standards.

The integration of precast technology at Suraksha Smart City has yielded numerous benefits:

- Structural Integrity: The precision-engineered precast elements contribute to the overall structural soundness of the buildings, enhancing safety and resilience.

- Aesthetic Versatility: Precast components can be molded into various shapes and finishes, allowing for diverse architectural designs that cater to contemporary aesthetic preferences.

- Cost Efficiency: The streamlined construction process reduces labor and material costs, making high-quality housing more affordable for residents.

Conclusion

Precast technology stands at the forefront of modern construction, offering unparalleled advantages in quality, durability, and efficiency. Suraksha Smart City's adoption of this technology exemplifies its commitment to delivering superior living spaces. As the construction industry continues to evolve, embracing precast technology will be instrumental in building resilient, sustainable, and aesthetically pleasing structures that meet the demands of contemporary living.

Wednesday | March 19, 2025